i’ve said it before but every type of button bounces. some more than others

and a simple switch debouncing routine

with some very small amount millisecond timer lockout

in the software would easily solve this issue.

this is such a common thing that there are button debouncing libraries for pretty much every popular microcontroller, embeded computer thing // programming language… arduino, teensy, python, etc etc

to make it easy for people to do this

It’s weird because the coder(s) seem very competent, that’s such an obvious thing. Maybe it’s more difficult with real time stuff, I don’t know but I wouldn’t want the timing compromised as well.

we’re talking about a very very small number to be sufficient in most cases

like ~10 millseconds

something that is far far under the speed an actual human could press buttons

even if they were trying as fast as possible

(which is more in the ~100 ms range)

so theres is very little to no risk of losing any timing in your button presses.

plus the debouncing routine only activates AFTER the first press.

the first press has no limitations whatsoever

the button routine itself is a simple mechanism

it sounds simple enough from the outsider perspective

but if they didn’t implement one from the start

(maybe thinking it wasn’t necessary?)

then it would be a big job to add to the firmware

basically EVERY SINGLE button press and combo function in the code

would need to be rewritten with the debouncing routine

very easy to make mistakes and break other things when doing something like that

even for the most experienced coders

having to then go back and check every single operation

to make sure things are still working as they should.

its do-able but its not trivial by any means.

I don’t mean the timing of button presses, I mean overall if you have that kind of scanning in the loop. I really don’t know, it depends on how the scheduling works but they’ve clearly prioritised event timing, it’s super tight.

It’s also not just normal key bounce at least in my experience, the keys can lose contact long (up to a second) after the initial press. Obviously that isn’t likely to be fixable in software.

But I’d be surprised if the keyboard routine isn’t the same globally. Of course it’s impossible to say without seeing the code.

ah i see what u mean now

good point

ime, the bounce routine overhead is negligible

compared to the normal scanning that is already happening.

i doubt it would make any difference in the timing and // or performance.

its very low level stuff and the processor they are using is pretty fast

would still likely fix most of the button triggering issues people are experiencing.

easy enough to implement & no hardware or major manufacturing changes would be required.

and would be available to all Z users, not just new ones.

seems like a win-win-win to me, atleast to try.

but ya u are right nobody knows except them.

of course i am only speculating.

maybe they tried it and scrapped it for whatever reason

like u said, they do seem more than competent to suss out something like this

Random, but you would know better than I since you disassembled the unit. I bought a used opz and the previous owner (i think its super glue) fastened the oplab into the Z. No way in hell Im removing it without damaging the actual Z correct?

You don’t. Deoxit D5 fixes it. Don’t use too much though, or your buttons will be stuck for a few days.

Alright so after almost a year with my op-z laying in my desk without being used because of the double triggers, I decided to dissasembly it at any risk.

About a year ago it started to show double triggers ramdomly. At the beggining it was only a few keys but after some time things got worst.

I tried with the method of the contact cleaner/

isopropyl alcohol (here in Argentina it’s impossible to get Deoxit D5). Not only it did not work, but also it got really worst after one week. It became totally unusable.

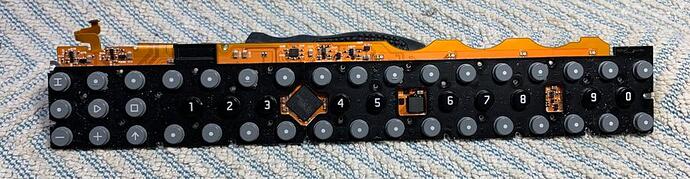

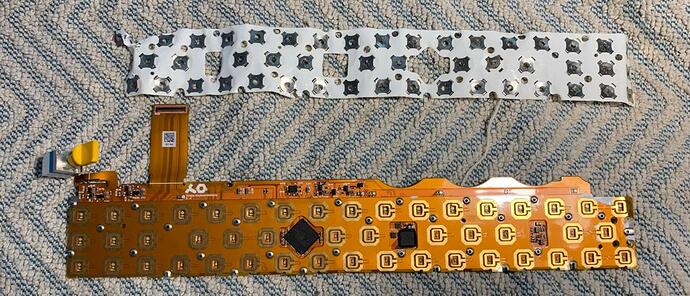

The plastic keys lay on the keyboard circuit. They are separated in two parts:

Just pull the plastic out

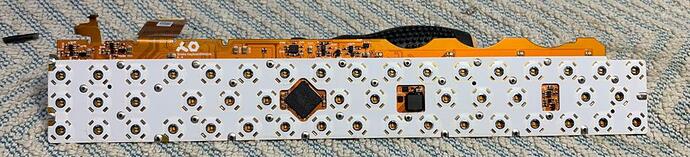

The keyboard itself consist of an aluminium plate with that type of “circuit tape” sticked on it. It also has a white tape with a lot of little pieces of metal (That is the top part of the button let’s say).

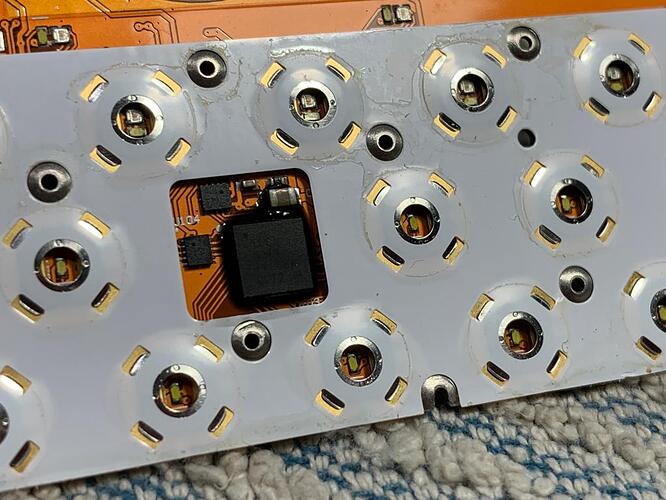

Here you can see that the rivets are gone

After some research, I decided to fully dissasembly it by using a small driller (those used for PCBs) I successfully removed all the plastic rivets. It was really easy and took me only 15 minutes to get rid all of them. Note: they fit in an angled hole on the aluminium plate.

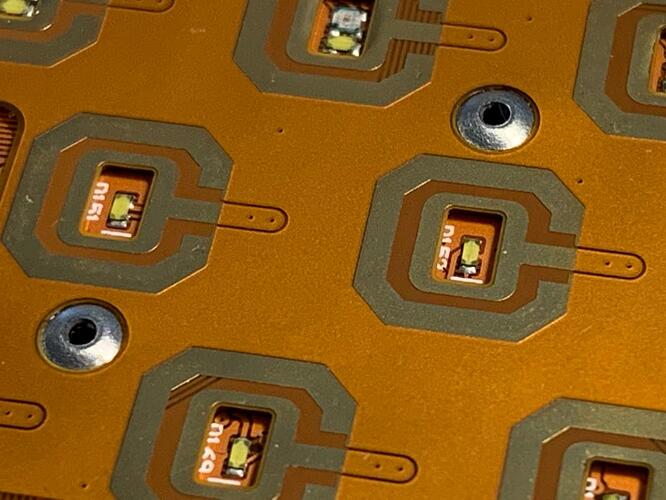

Now you can safely remove the whole keyboard and here there are several options to make it work: you can still try to clean it up with some contact cleaner (still did not work for me though) or you can carefully remove the white tape and clean both parts with a qtip and contact cleanner.

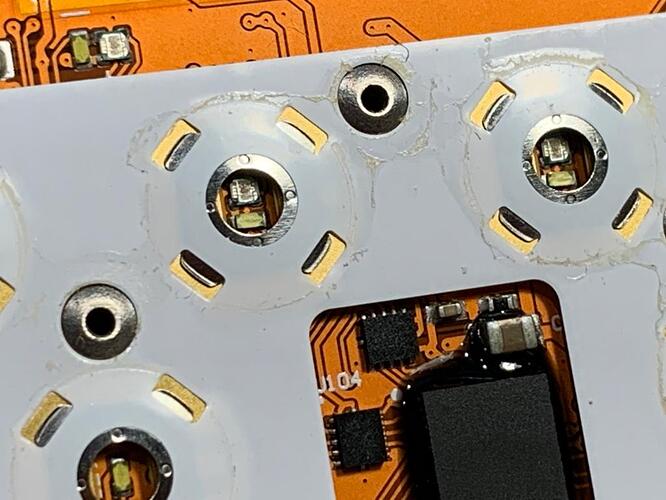

White tape removed

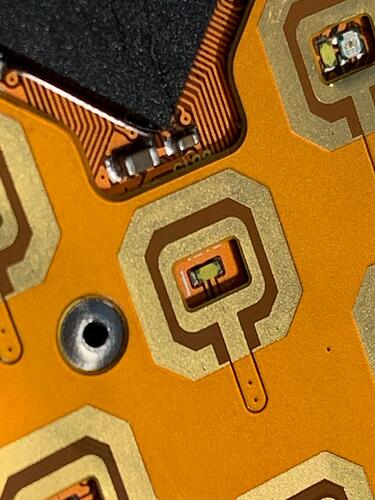

You need to clean the round metal part (top of the button)

And also the bottom contacts (on the brown contacts tape).

Once it’s done, just assembly everything back and it will work. The keyboard will be a bit loose and the buttons will remain somehow lower than what they were before, but it can be fixed by adding a piece of paper between the keyboard and the main board.

Keep in mind that the white tape will probably break at some point while it’s being removed even though being extremely carefully. In my case I used some adhesive transparent tape (scoth tape) to stick and keep the right position of three buttons whose part of white tape broke.

It’ve been some weeks since I did it and it still works perfect.

If you have any query just let me know.

Are the buttons attached to the black thing? Is there anyway to get them out without taking the keyboard off the front?

The domes are not gold plated, maybe they oxidized and caused the double triggers.

Good lord, that’s likely one of the worst keyboard designs ever.

I wonder if it’s worth soldering real buttons in between the contacts on the keys. Or even making an arcade button breakout box to put the OP-Z into with bigger buttons on a large case.

Wow that is…. Not what I was expecting. What a weird way to make a keyboard lol

I’ve seen that design before. On cheap microwaves and calculators. The design is prone to failure due to corrosion, or even bridging from any conductive or carbonised dirt.

The OP-1 has standard laptop keymechs which are far far better, but also larger.

It seems TE went for that for the small size.

OP, you could probably solder one of these between every contact:

Then drill out larger button holes on the top plate.